The cosmetic and personal care industries are growing at a breakneck pace. With global sales of $483 billion in 2020 and an annual growth rate of 4.75%, total revenue in the beauty industry is expected to exceed $716 billion by the year 2025, according to Common Thread Collective.

You may think that cosmetics are recent innovations. Surprisingly, or not, the history of cosmetics dates back thousands of years. We all can envision Cleopatra sitting on her throne with carefully painted seductress eyes; bright green malachite paste used by ancient Egyptians, deep blue lapis lazuli eye shadow with gold-colored pyrite flecks.

%20(400%20x%20276%20px)%20(200%20x%20276%20px).jpg?width=300&name=Untitled%20(552%20x%20276%20px)%20(400%20x%20276%20px)%20(200%20x%20276%20px).jpg) But it took some time for the usage of products by an elite few to become a viable industry. The definitive turn may have been in the 20th century when the upsurge of the film industry led the way with mass communication through fashion magazines, movies, and television.

But it took some time for the usage of products by an elite few to become a viable industry. The definitive turn may have been in the 20th century when the upsurge of the film industry led the way with mass communication through fashion magazines, movies, and television.

Enter stage left: greasepaint foundation developed by Max Factor in 1914 as a miracle for Hollywood stars.

Since then, the industry has boomed, and readily available skincare products have become an expected part of modern life.

A Vast Portfolio

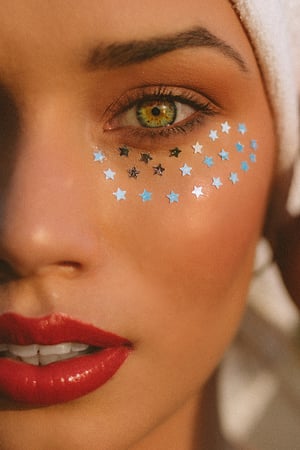

Like many consumer goods industries, the cosmetic market embraces a vast portfolio from skincare to makeup and beauty products. Makeup lovers delight in buying their favorite beauty brands or trying a new product for fuller lips, rosier cheeks, or thicker lashes.

Times are changing, and organic products are becoming more a part of both women's and men's beauty routines. In fact, the organic skincare product market is expected to reach a CAGR of around 8.5 percent between now and 2026.

As trends change and consumers continue their transformations, manufacturers diversify and push the boundaries of product and market expansion.

The Supply Chain

%20(400%20x%20276%20px)%20(200%20x%20276%20px)%20(1).jpg?width=300&name=Untitled%20(552%20x%20276%20px)%20(400%20x%20276%20px)%20(200%20x%20276%20px)%20(1).jpg)

According to Forbes, the beauty industry brings in sales of about $445 billion each year. That's a whole lot of products moving around the world. But have you ever stopped to consider the back-end process that keeps the goods moving?

Cue Supply Chain Management (SCM), or the management of the flow of goods and services between businesses and locations, incorporating raw materials storage, inventory management, and the movement of goods and commodities. Basically, end-to-end order fulfillment. The whole shebang.

With the rising demands of the cosmetic industry, as with many consumer goods markets, catering to various needs and satisfying a discerning target market necessitates efficient supply chain management.

As both cosmetic and beauty brands witness spectacular expansion, they become vulnerable throughout the supply chain. Quality assurance (QA) and supply chain management are essential for balancing market forces such as supply and demand. Nevertheless, the complexity around logistics and transportation makes management a common roadblock in this manufacturing sector.

Some Companies That Help You Look Good!

Let's discuss two of the most talked about cosmetic brands that bring a glamorous glow to people out there. We'll also look at how they faced the pandemic head on by changing their production to meet dire needs, strengthening their consumer loyalty in the process.

Mary Kay

Mary Kay Ash created Mary Kay Cosmetics in 1963 and since then, the company has become one of the most well-known skincare and cosmetics brands globally. Each year, the company spends millions of dollars in research and development to maintain quality, safety, and performance levels.

For a company that personalizes its products according to consumer demands, geographical differences are important. Mary Kay's Vice President Deanna Fell says, "We discovered that our Asian clients had quite different skincare requirements than our Latin American or American customers." It's easy to see how a global supply chain solution is critical to customer retention worldwide.

During the outbreak of Covid-19, Mary Kay Inc. dedicated a portion of its global supply chain and manufacturing resources to producing much-needed items, such as personal care and hygiene products (hand sanitizers), to help fight the virus. Altogether, Mary Kay contributed nearly $10 million in monetary and product donations across the world's communities.

L’Oréal Paris

L’Oréal has captivated consumers' attention since 1909 and now reaches over 130 countries, generating an annual sale of €23 billion. The beauty brand can boast one of the leading supply chain systems in the beauty industry with the resources of 7,500 supply chain experts worldwide working to help the brand meet real-time market expectations.

The process is driven by the company's mission, which focuses on consumers' mindsets and recent trends rather than solely on technological advances. Richard Markoff, L'Oréal's Corporate Director of Supply Chain Standards, describes the company's philosophy. "The team for me is the most important thing. Our customers drive the design of our organization. The supply chain is integral to the business strategy."

When Covid-19 broke out, L'Oréal prioritized the safety and health of the population ahead of routine production. The two brands L’Oréal Paris and Garnier worked together to produce and distribute 440,00 hand sanitizers (free) to doctors and medical staff.

Insights on Supply Chain Management

Let's explore supply chain management and the vital role it plays in the consumer goods industry.

Rising Freight Costs and Shipment Delays

Freight costs in the US amount to 6 percent of the GDP and are a significant expense within the supply chain. During the global Covid-19 pandemic, this issue has become even more volatile and troublesome for businesses. Manufacturing and shipping delays abound while congestion at key cargo ports restricts transportation. Freight rates fluctuate wildly amidst unreliable delivery times and lack of capacity. The workload put upon shipping departments has dramatically increased in terms of time, expense, and hassle.

A good course of action can be negotiating rates with compliant carriers with a history of reliable delivery to build a solid foundation for your supply chain. Often, transportation management companies can wield the necessary clout to get you the good deals.

Temperature Control

%20(400%20x%20276%20px)%20(2).jpg?width=400&name=Untitled%20(552%20x%20276%20px)%20(400%20x%20276%20px)%20(2).jpg) Nowadays, customers demand high-quality raw (often natural and organic) materials and ingredients, driving brand owners to use the finest products while ensuring sourcing and product transparency.

Nowadays, customers demand high-quality raw (often natural and organic) materials and ingredients, driving brand owners to use the finest products while ensuring sourcing and product transparency.

Temperature control is crucial to many sectors, such as cosmetics and fitness supplements, to preserve goods and avoid the spoilage and damage which occurs when goods are transported outside the desired temperature range.

Long-distance transport across air, railway, sea, and road increases complexity with lengthier shipping times. Add in today’s shipping delays, and the difficulty compounds.

Keeping temperature data logs of the moving cargo is paramount and using technology, for example IoT-enabled temperature and humidity sensors, can make the practice practical and scalable.

Customers Come First

Customer service is a core aspect of a manufacturer's overall strategy and lies close to the heart of the business. Nowadays, customers want complete transparency of their delivery status.

Beyond knowing when a shipment will arrive, customers expect goods to be on time and undamaged. So ensuring your vendors' compliance and improving on-time delivery is now business-critical. To strengthen your client relationships, as well as your reputation as a reliable manufacturer, partnering with an integrated logistics company that takes customer service as seriously as you do can be of help.

On-Time Delivery

According to Convey, only 77 percent of parcel shipments achieved on-time delivery in the US in April 2020 after the outbreak of Covid-19. The situation became relatively better in April 2021, when the on-time delivery shipments' ratio increased to 82 percent. At the same time, the cosmetic industry faced negative impact due to partial restrictions on travel and shipments.

Changing consumer lifestyles and trends, as well as social and environmental disruptions, also play roles here. The desire for people to pamper themselves, to feel and look better during a time of crisis, is nothing new. During World War II, the purchase of red lipstick spiked. And today, during the stressful times of Covid-19, little luxuries help us maintain our sense of self.

Changing consumer lifestyles and trends, as well as social and environmental disruptions, also play roles here. The desire for people to pamper themselves, to feel and look better during a time of crisis, is nothing new. During World War II, the purchase of red lipstick spiked. And today, during the stressful times of Covid-19, little luxuries help us maintain our sense of self.

Supply and Consumer Demands

In particular, the cosmetics and skincare sectors are caught in a supply-and-demand tussle. Consumers of beauty products are capricious, and today’s fashion can quickly fall out of style. As a result, manufacturers strive to promote the latest trends. Keeping up with crazes as fluid as Lady Gaga's hair color challenges suppliers and retailers to ensure that products are available.

End-to-End Supply Chain Visibility

In highly competitive industries, having extensive insight into the entire journey allows better management and advanced planning of the supply chain cycle. While the benefits of inducting a transparent supply chain are clear, this entails more than deciding what data to reveal to customers.

Companies must first gain deep visibility and understanding into their supply chains, including shipment tracking, carrier info, and rate trends. Business Intelligence can help drill down and interpret shipping data through custom dashboards. Lastly, merging shipping and accounts helps quotes, BOL, invoices, and payments become part of one seamless process.

What Does the Future Hold for Supply Chain Management?

Over the years, the supply chain has become a crucial cog that drives company performance, and firms thrive through adapting to a dynamic market. The entire supply chain management process depends on effective logistics, determining business-centric and tactical solutions to apply to end-to-end operations. Be it any business segment, gaining control over shipments will drive down costs, improve customer satisfaction and ensure steady profitability.

Please get in touch with us if you'd like to learn more about how a 3PL (Third-party logistics) like IL2000 can help you streamline operations and improve efficiency.