How we helped a company save over $800 on one shipment

Hi! Welcome to SF3.

Let’s talk about a quick way to save a smidge over 800 bucks on one freight shipment.

This whole situation played out in just one afternoon. Nothing huge happened. No brilliant supply chain maneuvering is in evidence here. But the situation we’re about to describe is just a solid example of how a sharp pair of eyes and the right skillset can hone in on one questionable supply chain decision and make it so much better.

We present to you the case of an embattled food packaging manufacturer dealing with tight delivery timeframes and ongoing freight staff retention issues. They sent us some incomplete shipping paperwork.

You’ll see how we filled in the gaps in this food and beverage supply chain brought in some much-needed consistency, and optimized one shipment to save a good chunk of change.

The upshot

- Improved carrier negotiations

- Avoided freight delays through proper classification and paperwork

- Saved over $800 on just one shipment

The sitch

To set you up with some context, this particular situation happened when retailers were struggling with empty shelves, and supply chains were creaking under the strain. Meanwhile, the Great Resignation had drained this company of key logistics personnel, placing additional strain on decision-making and process consistency.

This was the company’s difficult status quo when they partnered with IL2000 for help with logistics support. We’d only been working with them a little while when they submitted a routine shipping request.

The request was pretty scant on details.

Here’s what the paperwork told us: The shipment had to get from New York to Honolulu. They needed 11 items to go out, each weighing 25 pounds, each with identical cubic dimensions. A 12th package needed to go out to a different destination in Hawaii. No exact destination addresses were given. No details were given about freight type.

What was going wrong?

- There was incorrect carrier information: The company’s freight team wasn’t correctly classifying their freight, which effectively doomed their team to protracted and tricky carrier do-overs — with obvious negative knock-on effects for both time and cost.

- There was no process consistency: It was no one’s fault. They just weren’t up to speed on the shipping process and the precise paperwork trail that entailed. The particulars their freight team submitted were inconsistent from shipment to shipment and just inaccurate enough to cause big headaches further down the road.

- Cost-cutting measures were overlooked: Or at least, they didn’t know how to cut costs without compromising on efficiency. The company exhibited that all-too-common shipment-by-shipment mindset we talk about, where each item in their outbound freight was treated in complete isolation. It worked, sometimes. Sort of. But nothing about their freight operation was optimized for cost-efficiency.

The solve

When a new client is onboarded with IL2000, we assign their work to one of four in-house expert teams of supply chain experts. When this shipment request arrived, it went straight through to a team who knew the client’s product, their shipping lanes, and their unique supply chain challenges.

Drawing from that background knowledge, IL2000 was able to extrapolate what the company was shipping and brought some much-needed consistency to the paperwork. Crucially we were able to complete the missing classification data with the help of our world-class business intelligence system. That, in turn, meant the carrier would know how to handle the shipment and what rate to apply.

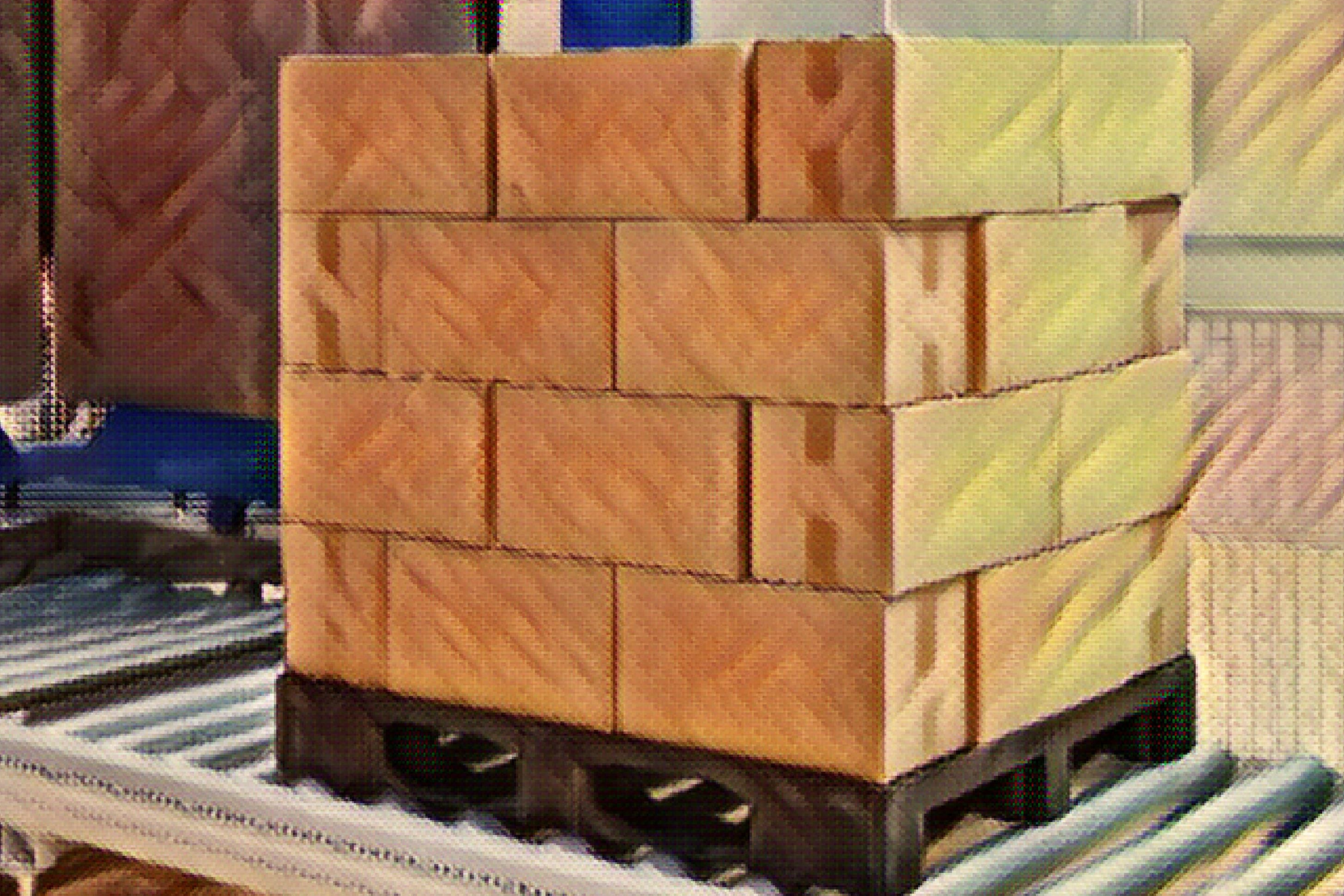

Still, something didn’t seem right. Our client was asking for express two-day air, but based on our understanding of their product line, they could easily get away with shipping the merchandise out using a slower method, thus saving considerable money in the process. After gathering more details about their shipment, we also realized it’d be feasible to bundle much of this shipment onto a single pallet. That’d save a lot of money in shipping. We floated a revised strategy and they gave us the green light. That same day their shipment was on its way.

Oh, and they’d just saved $837.25 on one shipment.

What went right?

- We smoothed out carrier negotiations: We were able to dive right into the complex business of freight classification and cleaned up their shipping paperwork. This paved the way for a smoother shipping process and greatly reduced the risk of shipping delays.

- We helped maintain shipping consistency: Our client was dealing with some serious freight staffing issues. Our team gave their supply chain operations continuity and were able to make sure that important processes weren’t being overlooked.

- We found a better way to ship: We saw a way to save significant money on a shipment through palletization and optimizing their shipping lane. We trained their team so that it’d be that much easier to realize similar savings moving forward.

The take-home

Sometimes we’re smart. Sometimes we’re insightful. But there are other times we just offer that thorough and detail-oriented eyeball you need to make sure your shipment goes out like it should.

Need help with not sweating the small stuff?