No, it’s not a Steve Martin movie.

As people spend more time at home during the pandemic, and work-from-home looks like it's here to stay, home renovation booms. Whether it’s an extension to create a new office space, turning the den into a baby’s room as let’s face it couples have had more downtime together, or a wooden fort for the kids that would make the Lost Boys jealous, DIYers and construction crews are battling unreliability of supplies.

Growth, growth, and more growth

Home improvement’s steady rise will continue as we go into 2022 and beyond.

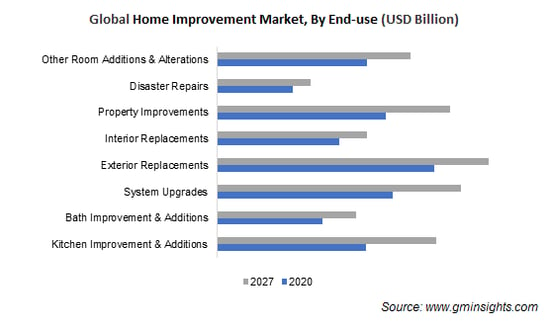

The global home improvement market surpassed USD 762.9 billion in 2020 and, with a compounded annual growth rate of 4.5%, will soar to an overall value of $1009.9 billion by 2027. Yes, you heard right – over 1000 billion dollars. This increase is across the board, from room additions to exteriors.

The global home improvement market surpassed USD 762.9 billion in 2020 and, with a compounded annual growth rate of 4.5%, will soar to an overall value of $1009.9 billion by 2027. Yes, you heard right – over 1000 billion dollars. This increase is across the board, from room additions to exteriors.

The past year has been exceptionally expansive for several reasons; a surge in the housing market, the stimulus driving down lending rates, and people spending more time at home. In fact, 76% of homeowners didn’t travel at all in 2021 (US Census Bureau).

Here are some fun facts for your next zoom cocktail hour. Home remodeling searches have doubled in the past year, kitchens remain the most remodeled room in the home, and home improvement companies have seen a revenue increase of 8.5% (HIS Markit).

When things aren’t going according to plan

While retail profits surged in Q2 of 2021, Q3 saw a sharp decline. But spending on house improvement is growing at twice the rate of other retail categories in the US, according to Comfy Living.

While retail profits surged in Q2 of 2021, Q3 saw a sharp decline. But spending on house improvement is growing at twice the rate of other retail categories in the US, according to Comfy Living.

This surge is contributing to a shortage of home improvement supplies. This is a new experience for most Americans.

“Homeowners who are probably used to simply walking into a major hardware store and picking up the items they need for home improvement projects or renovations may be surprised when they find empty shelves,” says University of Wisconsin economist emeritus Sandra Claflin-Chalton in an interview with Realtor.com.

So, why are we in this situation? What role do supply chains play in power tool availability for home improvements?

First, we need to understand the supply chain.

Supply chains began when humans evolved from hunter-gathers to more advanced civilizations. As populations grew, so did the need to move goods and materials from point A to point B. Vast ancient organizations, like the Roman and Inca Empires, had supply chains spanning the earth. They kick-started the world’s logistics in the form of roads, transport, and massive organized labor efforts. Though these empires dominate our view of the historic landscape, most supply chains were local in nature up through the 18th century.

Supply chains began when humans evolved from hunter-gathers to more advanced civilizations. As populations grew, so did the need to move goods and materials from point A to point B. Vast ancient organizations, like the Roman and Inca Empires, had supply chains spanning the earth. They kick-started the world’s logistics in the form of roads, transport, and massive organized labor efforts. Though these empires dominate our view of the historic landscape, most supply chains were local in nature up through the 18th century.

And then came rum, a shining example of a global supply chain network involving not just the movement of goods but also production. Labor, sadly in the form of slaves, was exported from Africa, sugarcane which evolved from India and Southeast Asia was grown and processed into molasses in the Caribbean, and distilleries in the US chugged out barrel after barrel of amber liquid carrying the flavor and aroma of the sugarcane plant a world away.

Taking a shot-glass-half-full perspective, we learned a lot during this global logistics experiment, but supply chains didn’t develop in leaps and bounds until the advent of the industrial revolution and mass production assembly lines. When Ford installed the first assembly line in 1913, the supply chain landscape changed forever.

Now we’re getting somewhere. While it might be appealing to paint your house with a drink of rum on hand, the connection to home improvement and spirits is faint at best. But with the advent of assembly lines, a clearer link to home improvement goods production materializes. Let’s keep going.

Now we’re getting somewhere. While it might be appealing to paint your house with a drink of rum on hand, the connection to home improvement and spirits is faint at best. But with the advent of assembly lines, a clearer link to home improvement goods production materializes. Let’s keep going.

Whether we're talking about the mass production of weaponry in America, the interchangeability of ship pulleys produced in England, or the use of standardized shipping containers by the US Army in WWII, supply chain management was formalizing.

Managing the chain

Logistics, or supply chain management, took hold in the 1970s with barcoding and computers for inventory and goods tracking. Technology sparked innovation in physical distribution management, albeit with a splintered focus and without central coordination.

The '80s saw the development of spreadsheets, modeling, algorithms, and map-based interfaces. Soon after, Enterprise Resource Planning systems (ERPs) and Electronic Data Interchange (EDI) allowed for even more supply chain and logistics tracking.

By the 1990s, globalization, spurred by the growth of manufacturing in China, brought with it widespread recognition of the term “supply chain management."

Today, global logistics is a standardized and technologically advanced beast whose “management” includes uniform shipping containers allowing movement between ship, rail and truck, electronic tracking for greater visibility, and business intelligence offering better control and planning.

Snap

How can something developed over thousands of years, finely tuned into a well-oiled machine, break down? Unfortunately, this is due to more than one broken cog on the transportation wheel.

Shortages across sectors, from rubber, plastic and wood to electrical equipment and electronics, make manufacturing a challenge right now. A wooden ring can't replace the rubber washer on your washing machine, even if it is readily available and at half the price.

Nor can a delivery company run without truck drivers, or contractors work without parts.

“Product shortages, labor constraints, transportation capacity issues, and shifting customer demands are only a few of the many reasons that we’re finding ourselves in a supply chain crisis at this time,” says Claflin-Chalton.

Back to home renovations as we go into 2022

Sure, there are workarounds for consumers, such as considering used appliances, buying leftover paint that was already mixed and not used, and renting power tools, but these are short-term fixes to a global crisis.

Research and Markets says 40% of consumers have a new hobby involving tools or home improvement. The surge is real, so what steps can retailers take to mitigate the effect of the supply chain meltdown on their business?

Don’t leave logistics up to chance

Using a robust Transportation Management System, or TMS, will allow visibility into every step of the supply chain and provide the tools to make swift, cost-efficient and inventive shipping decisions. No more forcing a square peg in a round hole. Use a TMS that caters to your specific business and logistics needs.

Consider Managed Transportation Services to set up shipments, manage claims, and troubleshoot transportation management problems. Think about it this way. You're hammering along, and every few whacks, you miss the nail and hit your thumb. If you brought in experts, not only would there be fewer sore thumbs, but if an issue arises, they're there to take care of it for you.

For many companies matching quotes and BOLs with invoices is like counting nails in a jar. Your guess is as good as anyone’s. However, a detailed freight audit and payment system can automate your freight payment process while reducing expenses and ensuring compliance with tight financial regulations.

Shed light on previously hidden opportunities

Business Intelligence, with a spiffy dashboard so you can absorb and act on data at a glance, moves you from fire-fighting and short-sighted thinking into accurate planning based on actionable insights. Going forward, you can pinpoint missed opportunities and identify new markets. Right now, that level of understanding could save a retailer.

As Steve Martin said, “Talking about music is like dancing about architecture.”

Relevancy? I’m going to stretch this one… Mismanaging logistics and pulling the covers over your head, hoping it will all go away, is like trying to fool your mom into believing you're sick on the first day of school. It won’t work.

But the potential for retailers to make transportation changes and find new revenue streams by anticipating shortages and recent demand surges in home improvements will have you dancing – whether over music or architecture is your choice.