In just a few years, packaging will likely be unrecognizable from what it is today. The industry has seen aggressive R&D investment in flexible, eco-friendly, and “smart” packaging, a trend that looks set to continue as consumer preference increasingly leans to ecologically ethical and highly customized product packaging. But getting to that brightly packaged future won’t be as easy as all that, especially considering some of the past packaging manufacturers’ experiences. COVID, The Great Resignation, and intense competition over shipping lanes create a steep mountain to climb.

Shippers need to understand the challenges and emerging developments in packaging that could be potential solutions.

Industry overview

Let’s look at first things first. The industry is evolving in response to customer behaviors. According to PakFactory, “As the world moves towards more advanced and sustainable methods, packaging manufacturers and consumers will benefit from efforts that will revolutionize customer experience, manufacturing & shipping, and environmental protection. Companies [that] anticipate these future trends … will reap the benefits.”

The packaging industry was valued at around 180 billion US dollars in 2019, with a forecast growth rate of 3.5% by 2026, market analyst Mordor Intelligence reports.

Despite the rapid growth and innovation across this industry, packaging supply chains face increasing pressures thanks to burgeoning shipping costs, a growing supply chain skills gap, and critical scarcities in raw materials.

Packaging manufacturers are looking for strategies to address these challenges — from setting expectations through transparent customer messaging to more elaborate solutions like supply chain restructuring, lane segmentation, and enhanced business intelligence dashboards.

This is a hotly competitive and rapidly changing industry, affected every bit as much by the gritty realities of an uncertain supply chain as the industry’s ambitious blue-sky thinking about what’s coming next.

Logistics challenges of consumer packaged goods and similar manufacturers

Packaging challenges are considerable in 2022 and beyond. The industry is impacted by materials and workforce scarcities, limited carrier availability, and increasing shipping prices.

Raw materials shortages

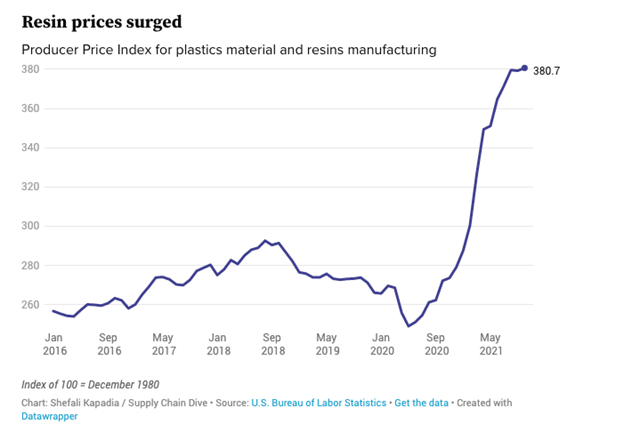

Worldwide shortages are impacting what packaging manufacturers produce and how quickly they produce it. Resin — a key ingredient in plastics — sits at the very base of the plastic packaging supply chain. Its limited availability is forcing companies to rethink packaging from the ground up. And this isn’t just happening at the retail level. Companies all along the resin supply chain are adjusting their inventory strategies, Supply Chain Dive reports, and prices on plastics are surging.

Manufacturers and retailers have to rethink how they package their products, which is impacting freight carriers, who are having to adjust their infrastructure and processes as new materials dominate the supply chain.

Securing carriers

Finding suitable carriers and then securing a competitive shipping rate are top of the list of challenges the packaging industry faces today. Demand for shipping and trucking lanes is significantly outstripping supply — a problem greatly exacerbated by the pandemic, climate volatility, and far-reaching shifts in the labor market.

In the United States, the truckload shipping market is a rising rate environment and looks set to remain that way for the foreseeable future. Truckload contract rates were up by close to 20 percent year-over-year, according to IL2000’s September 2021 update. Moreover, the LTL and Truckload Monthly Market Update November 2021 reports continued increases in diesel costs with no likely end in sight.

Packaging companies are looking for better ways to identify carriers they can reliably work with and at a rate they can afford.

A growing skills shortage

A critical and growing skills gap also constrains shipping. Today's trucking industry has a workforce shortage hovering at around 80,000 drivers, Chris Spear (CEO of the American Trucking Association) advised CNN in late 2021. This gap represents a record high in recent years and represents a roughly one-third increase from pre-pandemic levels.

While these problems are leaving a significant dent in many industries, the skills shortage is especially problematic in the packaging industry because packaging materials are typically fragile and often require specialized forms of transport. Packaging companies report a skyrocketing rate of damage in transit.

Price volatility

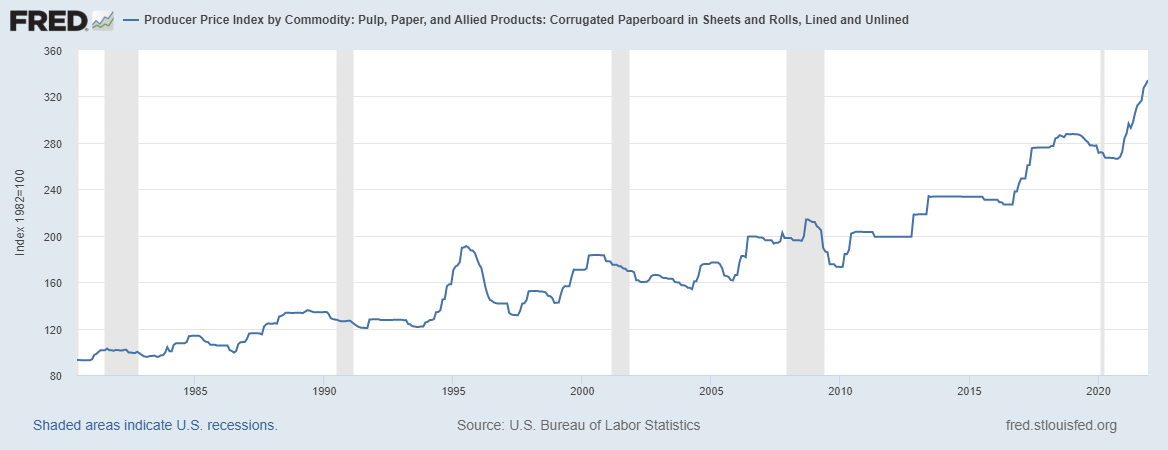

The packaging market has also become more volatile. As the pandemic and its associated complications have wreaked havoc across the packaging supply chain, prices for goods and services are changing to reflect this heightened uncertainty. Cardboard products are a telling example. Global prices in paper pulp increased by 30 percent in 2021, according to paper industry journal Pulp Paper News, with the secondary waste paper market rising five times.(FRED Economic Data, Dec 2021)

(FRED Economic Data, Dec 2021)

(FRED Economic Data, Dec 2021)

Emerging developments

Packaging will keep changing. New technologies will continue to be a leviathan of innovation, redefining the possibilities and relentlessly pushing out the industry’s limitations. However, at the same time, ambivalent consumer expectations look set to pull packaging toward the opposing (and possibly mutually exclusive) poles of hyper-customized messaging and eco-friendly simplicity. Lurking beneath these factors is a growing concern about counterfeit and consumer safety.

How does all that fit together? Your guess may be as good as anyone else’s.

Changing consumer expectations

“Conceptualisation through implementation is becoming increasingly arduous, with an exponential rise in demand for personalized packaging to allure consumers. Achieving right sizing and material downgauging, while maintaining aesthetics continues to be a critical challenge for most packagers.” (White Paper: Four Keys to Unlock The True Potential of Packaging, Future Market Insight, Feb 2020)

In much the same way that software and user interface design have undergone a renaissance of customer-driven simplification in recent years, the industry is observing changing consumer expectations around packaging simplicity. Less is becoming more. Consumer backlash against “packaging bloat” is becoming an increasingly common phenomenon. Retailers are more aware that a product’s popularity and reviews can soar or plummet purely based on the box it came in.

To stay ahead of this curve, packaging manufacturers are developing product feedback labs where consumer response to the packaging experience is analyzed and discussed. The “unboxing experience” is an art unto itself, carefully refined and impeccably curated. These and a raft of similar initiatives are likely to become crucial factors guiding innovation in the years to come. To keep up, the supply chain feeding this change process will have to display a similar commitment to innovate and (quite literally) think outside the box.

Smart technologies and personalized marketing

Building on the combined impacts of social media and the Internet of Things, the era of “personalized marketing” is likely here to stay. More than ever before is expected of packaging — and more than was even understandable just a few years ago. The incorporation of smart technologies (such as near field communication chips, QR code labels, and other emergent portable personalization tech) is forecast to contribute upward of 12 percent of packaging costs in the near future, Future Market Insight reports. The market analyst predicts that investment might double by 2030.

At the beginning of 2022, exactly where these emerging packaging trends will take the industry verge on the imponderable. However, companies in the space can confidently anticipate a rapid push toward smart and intelligent packing.

The rising stakes of counterfeit packaging

Undoubtedly, significant opportunity awaits early adopters in consumer-sensitive smart packaging. But counterfeit prevention company, Systech, also warns of the significant risks that innovative packaging manufacturers are likely to face as packaging expands in sophistication. Systech points to the pharmaceuticals industry as a telling “canary in the cage” for the future of packaging.

“Recent regulations in some markets for pharmaceutical products have led to the introduction of digital traceability programs. A compelling business case can be made for such a transformation in consumer packaged goods (CPG), durables and many other market sectors to provide similar benefits.” (White paper: The Promise of Connected Packaging, Dr Avi Chaudri, Systech, 2019)

The Force Majeure contractual challenges already wreaking havoc across packaging suppliers in the wake of ongoing disruptions since 2020 further reinforce that packaging suppliers are being challenged to balance the opportunities of this brave new world against legal risk and liability. Counterfeit and similar cyber threats only serve to raise the stakes.

Solutions

Communicating about the challenges

Some companies are taking a counter-intuitive step and openly talking about their packaging challenges, not just to their stakeholders and shareholders but to their customers as well. Thanks to the news cycle and the pervasive nature of materials shortages affecting every corner of our global economy, social awareness about global supply chain challenges is at an all-time high. Telling people about why your packaging is different or why, for that matter, orders are taking longer to fulfill is more likely than ever to reach a sympathetic ear.

The US Chamber of Commerce highlights in-store messaging, website content, and social media as critical channels companies can use to describe their supply chain challenges and set realistic expectations at the retail level of operation.

Rethinking the packaging supply chain

The outlook for packaging in 2022 has a lot of unknowns, but a near certainty is that delays and freight complications aren’t going anywhere. Manufacturers live in a world where inbound and outbound shipments need longer lead times and greater overall flexibility. Some businesses that are heavily dependent on particularly variable materials are taking extreme steps to find that flexibility, packaging advisory website PakFactory reports:

Another PakFactory report noted, “Businesses are opting for closer warehouses and packaging partners to help mitigate delays while gaining more control over lead times. Similarly, other businesses have now shifted their focus to diversifying packaging partners, manufacturers, and other parts of the supply chain to guarantee items.”

To state the obvious, these steps aren’t decisions a company should make lightly. And to aid in risk management, a growing number of packaging enterprises are investing in greater logistical insight across their supply chain before committing to such far-reaching changes. Managed transportation services offer a swift and cost-effective way to bring that knowledge into a company’s planning horizons.

Building more nuanced and adaptable shipping lanes

To mitigate rapidly rising rates and heightened shipping uncertainties, some packaging companies are taking a closer look at their shipping lanes.

By segmenting shipping across high, mid, and low volume lanes, packaging shippers are better positioning themselves to gain greater capacity to stave off supply chain uncertainties. For their high-volume lanes, they may opt for a solution offering fixed trucking fleet size, predictable rates, and a set delivery schedule. On the other hand, they gain the flexibility to contract out mid-volume rates to third-party carriers and use dynamic market-based pricing for their low-volume lanes.

Enhancing supply chain visibility with business intelligence

Taming a volatile packaging supply chain often begins with taming your logistics data using a BI dashboard. IL2000 specializes in building deeply customized industry-specific BI dashboards. These tools can bring focus and clarity to supply chain decision-making, seamlessly integrating historical data, revealing areas of untapped opportunity, and delivering instant alerts when a supply chain issue requires immediate attention.

Align your brand with the future of packaging by partnering with IL2000

The packaging industry is at a locus of marketing, logistics, and society’s evolving ecological awareness. Adding several layers to an already dizzying complex set of variables, technology seems to be on a course set to utterly transform what packaging looks like, with near field chips, QR codes, and endless materials innovations creating a creative soup of risks and possibilities.

Simply keeping up at a design and manufacturing level will be a challenge. And the challenge is compounded by the packaging supply chain, with its skills shortages and growing uncertainties. Increasingly, packaging enterprises will need pinpoint-accurate logistics data to drive nuanced and agile shipping solutions.

IL2000 is working with companies to drive those solutions. If you are looking for a partner that can help you innovate while keeping you ahead of that steep logistics curve, connect with a freight expert at IL2000 today. We’re the whole package.

Want to get in touch right now? Fill out the form below!